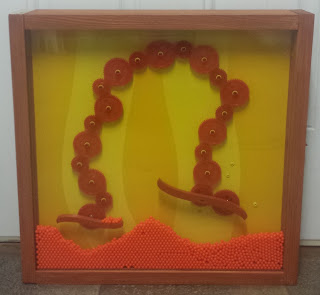

The challenge of making the pendulum "bend" in the middle was accomplished by adding some weight to the bottom. This causes gravity to be one of the affecting forces of the motion.

The magnetic force that keeps it in motion is accomplished with a permanent magnet, a hand wound coil magnet and a simple transistor circuit like this one:

The next couple of projects in the queue may require a little more finesse on the strength and timing of the magnetic pulses. So, as an alternative to this circuit, I'm looking into a programmable control circuit. More fun on the way!