I've been hearing tech people talking about Arduino for a while and with this project I got to satisfy my curiosity about them.

Since the project didn't require much memory or processing speed, the Arduino Nano was quite sufficient for the job. Its a tiny little thing less than 1.5 inches long.

It conveniently works with Neopixel LED strings. The set I chose is this style allowing me to place individual lights right where I wanted them.

So the Arduino and the Neopixels are mounted like this on the back of the project.

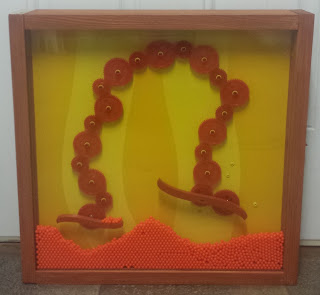

So that the front of the project looks like this:

Best seen as a video: